Call : +8615943028902

CHANGCHUN WELLTECH INDUSTRY CO., LTD.

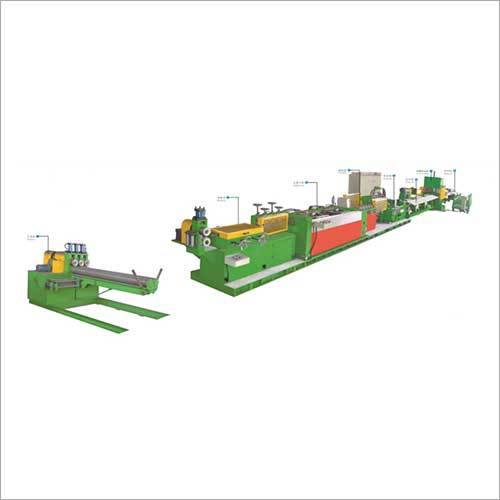

Introducing high-end products like Heavy Duty CNC Roll Grinding Machine, Wire Drawing Machine, Hydrogen Generator, Nydrogen Generator, Oxygen Generatory, Cold Roll Forming Machine etc.

- New Arrivals

- Featured

About Us

Ever since the beginning of our company, Changchun Welltech Industry Co., Ltd., in the year 2009, we have been a premier manufacturer, supplier and exporter of high-quality products like Hydrogen Generator, Nitrogen Generator, Oxygen Generator, Roll Grinding Machine, Wire Drawing Machine, Cold Roll Forming Machine, Tube Mill, etc. We constantly commit to delivering complete solutions for customers, offering customized R&D, production, installation, commissioning, maintenance, and operating support for metallurgical machinery and equipment, relying on four large R&D and production centers in Yantai, Dalian and Wuxi. All our products are based on modern technology and consistent quality and they not only have a large share of the local market, but also have a solid reputation in Asia and Africa.

Manufacturing Machines Used

We own more than 400 sets of numerous CNC machining centers, CNC lathes, CNC planer type milling machines, precision grinding machines, digital readout boring and milling machines, CNC drilling machines, CNC cutting machines, Japan Toshiba CNC precision boring machine, Swiss CNC precision cylindrical grinding machine, CNC worm grinding, CNC machining center, dual-frequency laser interferometer, resin sand molding and blank casting production, three coordinates Machines, roundness meters and other advanced technology equipment and complete supporting testing equipment, etc. For different CNC machine product design and development, rough casting, production, inspection, and measurement, we have a complete system of process equipment.

Application of Products

Our products like CNC Roll Grinding Machine, CNC Centerless Grinding Machine, Cold Drawing Machine, Cold Roll Forming Machine For Ridge Cap Profile, etc., are used in a variety of industries, including metal processing, metallurgical fields, roll processing, non-ferrous processing, ships & auto parts & bearings &bring material processing, steel tube production, welding wire processing, cold-formed steel manufacturing, galvanized steel sheet production, stainless steel welded pipe equipment manufacturing, and so on. Some of our machines are also used in the metallurgical, paper making, float glass, chemical, oil and grease, electrical power, aerospace, nuclear and military industries.

Quality Checking Process

Our quality checking process includes the following factors:

- We have professional testing equipment to suit diverse machine manufacturing needs.

- We also employ second-time checking for outsourced parts, ensuring machining precision, quality, and stability of the entire machine and critical components.

- We guarantee that every machine has gone through a thorough quality inspection, before leaving our facility.

Back to top

|

CHANGCHUN WELLTECH INDUSTRY CO., LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry